Routine Maintenance of Asphalt Mixing Plant

- Share

- Issue Time

- Dec 5,2023

The maintenance

of asphalt mixing plant plays a vital role in ensuring the normal operation of

the equipment and extending the service life. Below some key points for

maintenance of asphalt mixing plants:

1. Daily

Inspection: Regularly inspect various parts of the equipment, including

mixing tank, vibrating screens, conveyor belts, dust collectors, to make sure the

normal operation and less damage.

2. Cleaning

and Maintenance: Clean the equipment on a regular basis, remove accumulated

asphalt and debris to keep the equipment clean and hygienic. Pay special

attention to the dust collector cleaning to ensure it is working properly.

3. Lubrication

Maintenance: Regularly add lubricating oil or grease to the lubricating

parts of the equipment to make sure the normal operation of the friction parts

of the equipment and prevent damage caused by friction.

4. Regular

Maintenance: Conduct comprehensive maintenance of the equipment on a

regular basis, including checking and replacing wearing parts, adjusting the

working parameters of the equipment, and ensuring the performance and accuracy

of the equipment.

5. Safety

Inspection: Carry out regular safety inspections to ensure the safe

operation of the equipment. Check the electrical system, pneumatic system,

hydraulic system, etc. to guarantee their normal operation, safety and

reliability.

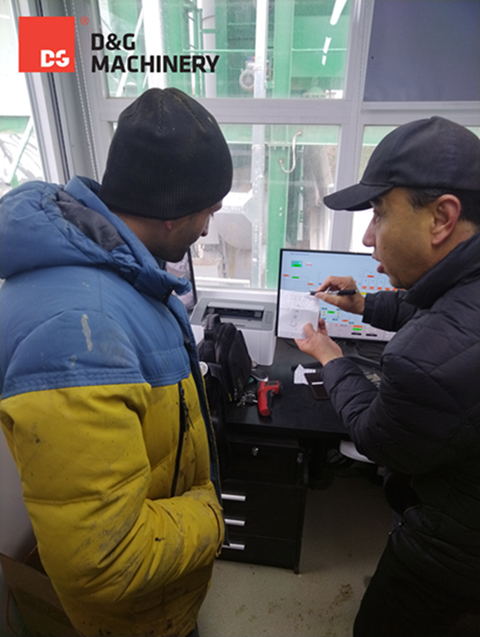

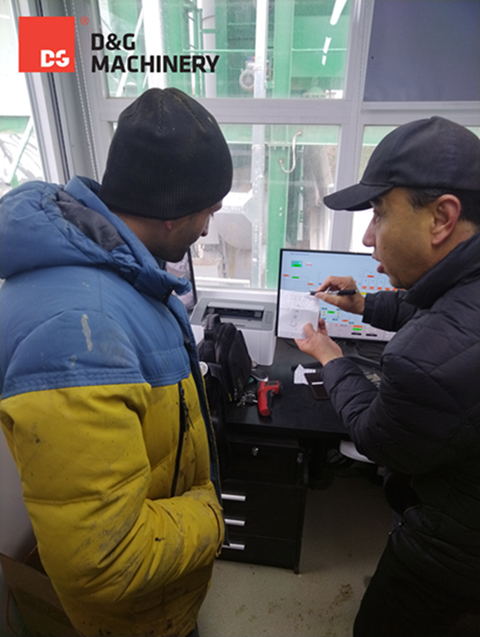

6. Train and cultivate maintenance personnel: Ensure that equipment maintenance personnel have the necessary skills and knowledge to operate and maintain the equipment correctly.