New Year Upgrades with Special Discounts —— Introducing D&G Machinery Self-cleaning Dryer Drum

- Share

- Issue Time

- Mar 19,2024

Summary

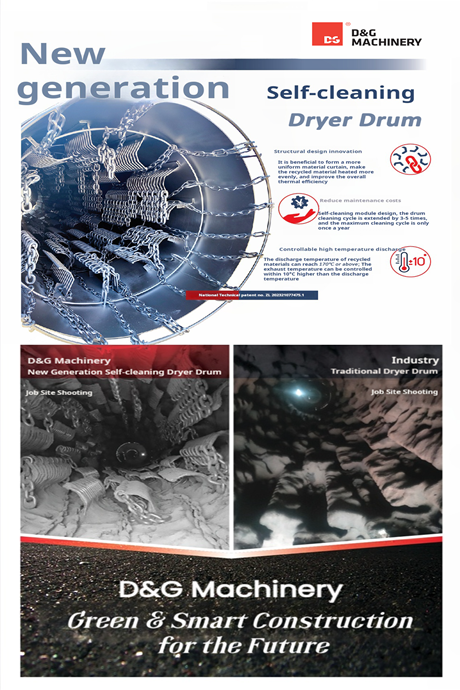

After years of continuous R&D and experiment in the field of asphalt recycling plant, D&G Machinery has designed and developed a new generation of "self-cleaning" dryer drum patented technology with structural innovation. Read on to find more.

Are you still struggling with the constant cleaning of the recycling dryer drum?

Are you worried about not able to raise the discharge end temperature, resulting in low thermal efficiency?

Are you frustrated with the low RAP addition ratio?

After years of continuous R&D and experiment in the field of asphalt recycling plant, D&G Machinery has designed and developed a new generation of "self-cleaning" dryer drum patented technology with structural innovation, which will completely settle these problems for you!

On the occasion of the New Year, D&G Machinery will help you upgrade and retrofit your recycling dryer drum at the most preferential price before March 31,2024! If there are these problems for your recycling dryer drum, no matter what brand or model it is, do not hesitate to reach us for a detailed solution with special discount! After April 1,2024, the product will restore to the original price.

According to calculations, for every 10℃ increase in the exhaust gas temperature of the recycling dryer drum, fuel consumption will increase by 1%. Please refer to the following table for details.

|

Production

Temp.at 5% Moisture Rate(℃)

|

Recycling

Flue gas Temp. (℃)

|

Fuel

consumption per ton (Kg)

|

Increase

in fuel consumption benchmarking baseline

|

|

140

|

150

|

6.18

|

Baseline

|

|

140

|

160

|

6.24

|

1.0%

|

140 | 170 | 6.30 | 2.0% |

140 | 180 | 6.36 | 3.0% |

140 | 190 | 6.43 | 4.0% |

|

140

|

200

|

6.49

|

5.0%

|

As per the data above, assuming a high exhaust gas temperature at 200℃. The additional fuel consumption compared with 150℃ would be 0.31kg. Based on a price of CNY4,000(approx. USD556.14) per ton for heavy oil, the additional cost would be CNY1.2 per ton. If the annual production of recycled material is 100,000 tons, it would result in a waste of CNY 120,000(approx. USD16,683.72) in fuel costs. This would also bring about increased carbon emissions and environmental damage.

In addition, the frequent cleaning of RAP, for instance twice or three times a month, consumes both manpower and money, causing delays in production schedules. Actually, the cost of cleaning exceeds that of wasted fuel in most cases!

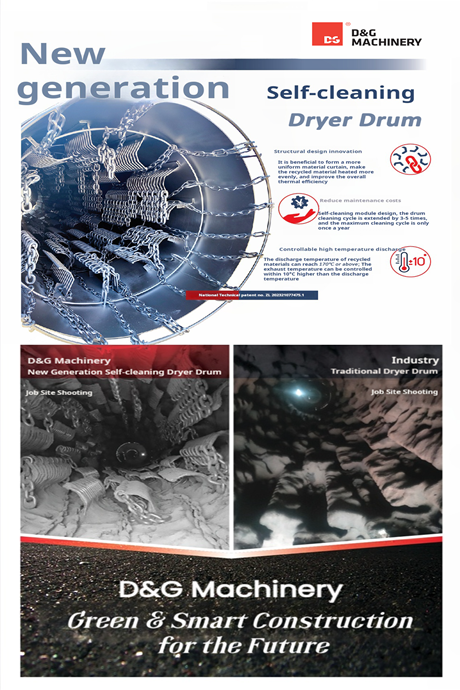

Photos above: RAP flue and material temperatures

Therefore, for users, the economic efficiency and environmental friendliness of a plant during operation are of paramount importance.

The patented product-Self-cleaning Dryer Drum launched by D&G Machinery has very obvious advantages:

1. Much Less Maintenance Costs

The dryer drum's cleaning cycle can be extended by 3-5 times thanks to the self-cleaning module design, with the longest cleaning cycle only one cleaning yearly.

2. High-Temperature Discharge

The maximum discharge temperature of recycled material can reach 170℃ or above, and the exhaust gas temperature can be controlled to be only 10℃ higher than the discharge temperature.

3. Innovative Structural Design

The design promotes a more uniform material curtain, ensuring even heat distribution throughout the recycled material thus lifting overall thermal efficiency.

4. Higher Addition Ratio of RAP

Ensure consistent equipment productivity to meet production requirements.

Take Action and Benefit NOW!

Don't miss out the good opportunity to boost your plant's efficiency and profitability with our patented technology. Contact us now to learn more and start your wonderful retrofitting journey!