The New Favorite in the Regeneration Field - Foamed Asphalt Cold Recycling

- Share

- Issue Time

- Aug 23,2024

Summary

As the asphalt pavement ages, a large amount of reclaimed asphalt mixture (RAP) is generated during maintenance and repair processes. The rational and efficient recycling of these materials has become a hot topic in current road construction. Foamed asphalt cold recycling technology, featuring stable technical performance of the finished material and relatively low production costs, has been gradually applied and promoted in the area of road maintenance in recent years.

As the asphalt pavement ages, the pavement undergoes natural oxidation and heavy traffic loads, leading to a gradual acceleration of its deterioration. Consequently, a large amount of reclaimed asphalt mixture (RAP) is generated during maintenance and repair processes. The rational and efficient recycling of these materials has become a hot topic in current road construction. Foamed asphalt cold recycling technology, featuring stable technical performance of the finished material and relatively low production costs, has been gradually applied and promoted in the area of road maintenance in recent years. It boasts outstanding usage results, becoming the "new favorite" in the field of recycling.

Technology Overview

Foamed asphalt cold recycling technology involves injecting room-temperature water into hot asphalt, causing the asphalt to expand and form asphalt foam. The foam is mixed with RAP at a certain ratio, along with new aggregates, active fillers (such as cement and lime), and water, all at room temperature. Then the mixture is paved to form a pavement structural layer, which has a mechanism that lies between rigid and flexible bases, primarily suitable for use as an upper base layer or underlayment of asphalt pavement. The technology not only maximizes the "residual value" of old asphalt mixtures, promoting the circular reuse of old pavement materials, but also significantly reduces energy consumption in the exploitation of virgin aggregate resources, mitigates environmental pollution, therefore achieving the resourceful reuse of RAP and contributing to the low-carbon and green transformation of road maintenance.

Technical Characteristics of D&G Machinery's Foamed Asphalt Cold Recycling Technology

1. Energy-saving and Eco-friendly: Only the heating of asphalt is required, no aggregates heating needed compared to hot-mix asphalt mixture production, thereby saving energy and reducing energy consumption. Additionally, this technology help consume plenty of RAP generated from asphalt pavement renovation, cutting down environmental pollution.

2. Easy and Efficient Construction: The simple production process for the finished material using this technology brings high yield

and fast construction, meaning less impact on traffic during construction. Traffic would be restored rapidly on the proceeded pavement, alleviating traffic congestion and inconvenience caused by construction.

3. Excellent Performance: The foamed asphalt cold recycling mixture can be used as an asphalt underlayer or upper base layer with outstanding performance. Meanwhile, this technology enables the conversion of semi-rigid bases into semi-flexible bases, extending road lifespan and reducing maintenance costs.

4. Remarkable Economic Benefits: This technology significantly enhances the overall economic benefits of road projects by conserving substantial amounts of materials (new aggregates) and energy costs (compared to hot-mix asphalt mixture), as well as reducing construction cycles.

Application

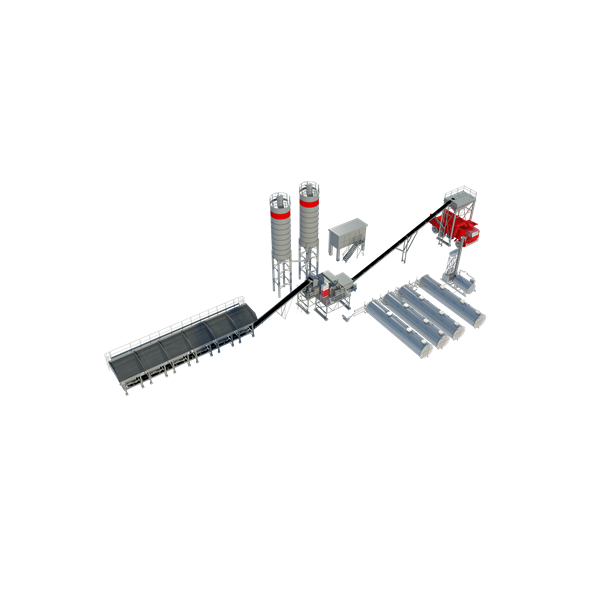

D&G Machinery in Action: As an industry and technology leader, D&G Machinery embraces bold experimentation and technological advancement. In 2021, through in-depth collaborative research with the Research Institute of Highway, Ministry of Transport, and extensive engineering practice validation, D&G Machinery launched a complete set of foamed asphalt cold recycling equipment (featuring a new continuous asphalt foaming device, patent No: ZL 2022 20853100.9), achieving exceptional usage results and user experiences.

The process of this equipment can also be applied to upgrade and transform existing aged water-stabilized mixing plants into continuous foamed asphalt cold recycling systems (with the option of supporting emulsified asphalt device). Currently, this upgrade has been successfully applied to various brands of water-stabilized mixing plant. For example, a customer in Jilin Province,China retrofitted a model 800 water-stabilized mixing plant of a domestic brand with an asphalt foaming device in 2023, upgrading it into a continuous emulsified asphalt cold recycling plant.

Prospects and Outlook

With an increasing need for road maintenance and higher requirements of environmental protection, there would be a broader development prospect for the foamed asphalt cold recycling technology. We believe this technology will witness further promotion and application in the following aspects:

1. Technology Upgrade: Targeting the problems of foamed asphalt cold recycling technology at present, such as relatively low mechanical strength, technical optimizations and upgrades will be conducted. By improving gradation design, construction processes, and additive usage, the mechanical properties and durability of the mixture will be strengthened.

2. Market Promotion: There would be more market promotions to raise industry awareness and acceptance of foamed asphalt cold recycling technology. Technical knowledge will be spread through technical exchange meetings, training sessions, thus accelerating application.

As the "new favorite" of the recycling field, foamed asphalt cold recycling technology has immense development potential and significant application value in the field of road maintenance. If you are interested in the technology and the application to your equipment, do not hesitate to contact us.