Production Facilities

- Share

Introduction to our main production facilities

A. Automatic processing equipment

1. Automatic welding robot

Be responsible for the welding of critical parts of screen, dryer drum and other components.The welding parameters for each weld are constant during welding, providing stable welding quality and ensuring the consistency of parts. Greatly improve the working conditions, workers only load and unload work pieces, far from welding arc, smoke, noise and other pollution;Improve labor productivity and keep constant production cycle.

2. CNC plasma flame cutting machines

Be responsible for cutting all kinds of plates according to size.The advanced machine with high accuracy and fast cutting speed perform the high working efficient and quality standard.

3.Precision shot blasting equipment

Be responsible for mechanical derusting of all workpieces to ensure that the surface of workpieces can meet the conditions of spray.Shot blasting, carried out under sealed conditions with dust exhaust apparatus, can reach the specified rust removal grade and obtain even finished surface; closed operation without dust flying;high speed, high efficiency and stable quality.

4.CNC bending machine

Be responsible for bending various plates.

High-precision grating ruler avoids the influence of machine body deformation on bending accuracy, with higher bending precision, and the influence of bending operation on workpiece deformation is minimized.

5. CNC shearing machine

Be responsible for cutting and blanking of plates.

The equipment has the advantages of simple operation, high accurate processing and high production efficiency.

B. Environmental protection facilities and equipment

As national and global environmental protection requirements become more and more strict, our company has invested heavily in environmental protection facilities and equipments to build an advanced pump-free water curtain spray chamber. The discharged gas meets the standard through the treatment of pump-free water curtain spray paint processing. The company is equipped with 40 sets smoke and dust processors of various models and specifications, effectively and timely dealing with the smoke and dust produced in the production process. Greatly improve the working environment and the working conditions of employees.

1. 5 Fixed spray paint drying rooms

2. 3 retractable dry type spray booths

3. Pump-free water curtain paint mist treatment equipment

4. Smoke dust processor (Pulse type, central type, fixed type, mobile type)

Smoke dust processor - fixed type

Smoke dust processor - mobile type

C. Production equipment

1. Graco Spraying machine

American Graco spraying machine, with precise control parameters and stable performance, ensures the painting quality of the product.

2. Carrier roller heater of dryer drum/Bearing heater

Heating by electromagnetic induction principle, with easy and simple operation,even heating, and Environmental protection in production process.

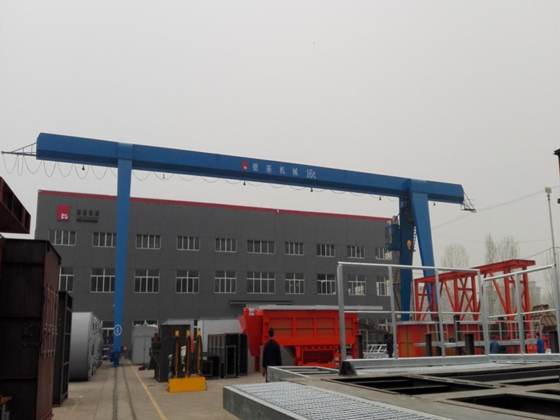

3. Crane

The company is equipped with gantry, single beam and cantilever cranes of various specifications and models to meet the needs of production packing, storage, transportation, receipt and delivery.

D. Dedicated test bench

1. Dedicated test bench of mixer

2. Vibrating screen test bench

3. Test-bed of dryer drum