DGX Series DGXR4500/DGXR4500D asphalt mixing plant

- Model

- DGXR4500/DGXR4500D

Item specifics

- Standard configuration

- Light oil / heavy oil

- Rated capacity

- 320~360 t/h

- Filtering area

- 1584 m²

- Screen mesh quantity / Screening area

- 6 / 58.7 m²

- Place of origin

- China

- Application

- bituminous pavement

- Product name

- DGXR4500/DGXR4500D

- Brand

- D&G MACHINERY

Review

Description

Product feature

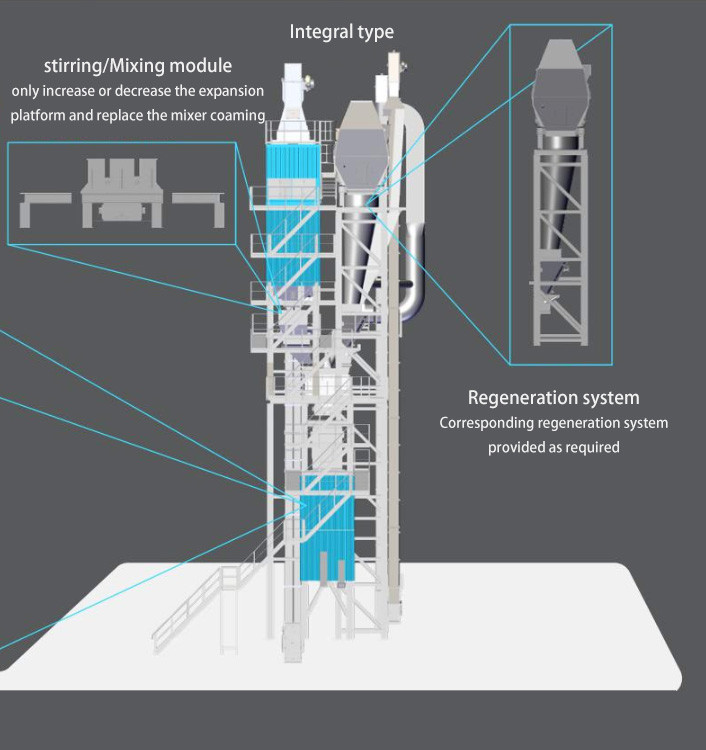

The use of [ integral type] equipment for the production of reclaimed asphalt mixture has the unique advantages. For users who clearly need to use regeneration, there is no doubt that [integral type] devices will be chosen. Not all users have the demand for regeneration, at least for the time being, regeneration may not be used temporarily. For such users, they often get into a dilemma when selecting equipment. In the end, how to choose: whether to meet current needs and choose [conventional type] first, or choose [integral type] for long-term planning in one step.

As for the equipment that needs to be relocated according to the project, different projects have different requirements for equipment. For example, the demand for regeneration (regeneration mode and addition proportion), requirements for finished product storage bin (whether it is matched, the capacity and the number of compartments), supporting devices to meet the needs of different production processes (such as: Warm Mixing foaming device, additive device, etc.), equipment combination and matching carried out by users according to the needs of the project.

DGX is a product developed in line with the principle of allowing customers to choose more freely and use more flexibly. Modular design makes equipment assembly like [transformers].

Integration by requirements

DGX adopts the idea of cross model planning and design,

functional modules are integrated according to different modes,to realize the conversion of different equipment styles and functions,to meet the different requirements for different production conditions.

Multiple function expansion devices are optional

·Regeneration cold drop system

·Reclaiming agent metering adding device

·Warm mix asphalt foaming device

·Powder / particle additive metering adding device

·Liquid additive metering adding device

Realize various types of mixture production functions

·Conventional hot mix asphalt

·Reclaimed asphalt mixture

·Warm mix asphalt mixture

·Color asphalt mixture

·Special asphalt mixture(Such as SMA, etc )

TECHNICAL DATA

|

MODEL |

DGXR4500/DGXR4500D |

|

|

Rated Production Capacity |

320~360 t/h |

|

|

Cold feeder bin |

Number × Volume |

6 × 18 m³ The number of compartments can be customized •Optional: automatic batching system |

|

RAP cold feeder bin |

Number × Volume |

2 × 12 m³ The number of compartments can be customized |

Virgin aggregate drying | Diameter × Length | Ø2.8 m × 12 m |

System | Drying capacity | Mixture discharge temperature 160℃(Ambient temperature 20℃) |

Moisture content 3% | 390 t/h | |

- Moisture content 5% | 330 t/h | |

Maximum output power of burner | 26.7 MW | |

Fuel type | Standard configuration:Light oil / heavy oil •Optional:Natural gas / pulverized coal | |

RAP drying system | Diameter × Length | Ø2.2 m × 11 m |

Drying capacity | Mixture discharge temperature 140℃(Ambient temperature 20℃) | |

- Moisture content 5% | 160 t/h | |

Maximum output power of burner | 11.2 MW | |

Fuel type | Standard configuration:Light oil / heavy oil •Optional:Natural gas | |

Dust removal system | Dust filtering method | (1st stage) Pre-separator +(2nd stage)Bag filtering •Optional:first-grade cyclone separator |

Filter bag quantity | 960(480 + 480) | |

Filtering area | 1584 m² | |

Mixing tower | Screen mesh quantity / Screening area | 6 / 58.7 m² |

Hot bin quantity/ Overall volume | 6 + 1 / 75 m³ | |

Aggregate weighing | 2 × 4000 kg(Double-scale) | |

Filler weighing | 700 kg | |

Bitumen weighing | 500 kg | |

RAP weighing | 3000 kg | |

Volume of RAP hot bin | 9 m³ | |

Mixer capacity | 5500 kg | |

Mixer power | 2 × 75 kW | |

Rated mixing capacity | 440 t/h | |

Mixing form | double-horizontal shafts / dual motors / Synchronous reducer | |

Filler metering/ Feeding mode | Double frequency conversion screw / compelled and well-distributed feeding design | |

Bitumen metering/ Feeding mode | Dynamic 、Secondary measurement /high pressure uniformly spray | |

RAP metering / Feeding mode | Cumulative measurement of cold and hot RAP / feeding into the mixer directly | |

Hot mix storage bin | Hot mix storage bin under mixer | Standard configuration:single-span double compartments 70 (35 + 35) m³ |

Storage bin by side | 120m³ | |

Bitumen system | Standard configuration | Heat conduction oil heating, 50000 liters horizontal asphalt tank (the number of tanks can b |

Optional | Electric heating system, vertical asphalt tank, tank capacity and quantity can be configured as | |

Filler system | Standard configuration | stack-up filler silo,storage bin under mixer 100 + 60 m³ / storage bin by side 50 + 80 m³ |

Optional | Additional overhead or floor filler silo or filler elevator | |

Control system | "DGLeap”fully automatic production management system, laser printer, fully automatic IPC, Touch screen electrical automatic + Manual multiple redundant control system,“DGLeap iCloud Remote Service System, Good heat and sound insulation | |

Environmental standards | Dust density | ≦20 mg/Nm³ |

Blackness | Ringelmann Blackness Class 1 | |

Noise in control cabin | Ncc ≦70dB | |

Production standard | Factory standard/ Industrial standard/ National standard/ CE standard,To the highest standards | |

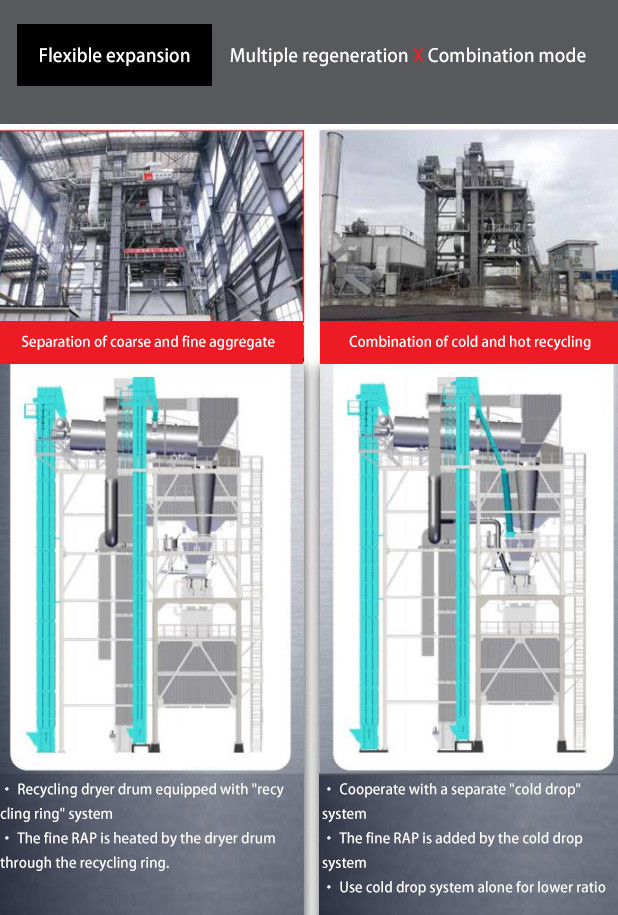

Optional configuration | • Warm mix asphalt foaming device | • RAP dryer drum “recycling ring” system |

• “Cold drop” regeneration system | • Powder / particle additive metering adding device | |

• Liquid additive metering adding device | • Reclaiming agent metering adding device | |